| What you need to know Fashion trends Craftsmanship Collections About GLENI |

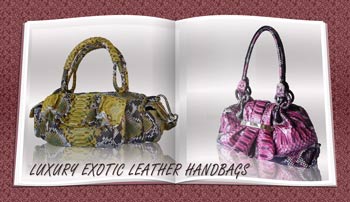

WHAT WORKING PROCESSES DO WE GO THROUGH TO CREATE A LUXURY BAG THAT IS 100% HAND-MADE IN ITALY ?  In this article Gleni would like to give you a short explanation of the various working processes that go into the creation of our luxury handbags, so that you can get a better idea of the commitment and meticulous craftsmanship that our artisans devote daily to every step of the production of each bag, and above all the amount of passion they put into everything they do, from the cutting out of the leather to the delicate finishing touches that embellish our products. We've left out some of the more technical processes and summarized some of the finer details, to give you an interesting overview of the whole production process, that we hope you will enjoy reading! Our handbags, as we've mentioned elsewhere, are completely made by hand, without any use of industrial machinery, except for a simple sewing machine, which is mostly used for the fine finishing of the product. Everything else is in the hands of our skilled Italian artisans, who bring to their profession the utmost commitment and years of experience in order to produce a bag that is proudly Made in Italy, an article that is so perfectly finished and beautiful that it will never go unnoticed. But how are these wonderful 'jewels' created? However the designer should not base the design of the new model exclusively on the latest fashion trends, but should take into account the type of exotic leather that will be used to make the handbag. For example if the bag will be made from genuine python or ostrich, which are both very soft and supple leathers, he will need to develop a design that takes advantage of the softness of the skin, and again, if we want to make a new Ligator croc handbag, we will be looking for a more structured design, as this leather is much firmer and more compact. It would be very difficult, if not impossible, to adapt a design created for python or ostrich leather to use with our crocodile or Ligator croc leathers! Every skin has particular qualities that suit it to make certain models of handbags, which show off its amazing elegance and prestige to best advantage. MASTER LEATHER CRAFTSMAN, decides which of the many models submitted by the Designer are most suitable for the new collection and would work best with the type of leather for which they are designed. After having chosen the model, we move on one of the most important moments of the production process: the making of a prototype of the bag in paper. Sometimes one person, who is especially expert and experienced in the leather sector can take on more than one phase of the production at the same time, but more often the making of the prototype is entrusted to a specialist PATTERN MAKER, who works from the drawings produced by the Designer and transfers his ideas on to paper to create an actual paper model of the bag. It is at this stage that the bag, which may already have become quite different to that created by our designer, begins to take shape.  Once the paper model of the bag is perfected, it is time to prepare the materials, that is the leather, from which to shape our final product. Here we meet another very important professional figure: the LEATHER CUTTER, who skilfully cuts the leather needed for each bag and prepares it for stitching. This is a very intricate and precise task and needs a wealth of experience of leather working, to be able to make the best use of the leather at his disposal, avoid any wastage and above all be able to recognise the special qualities or defects of the particular skin he is working with. This work is entirely carried out by hand and becomes even more difficult when using valuable leathers, where the slightest error or wastage means that considerable amounts of money are wasted, and so you absolutely have to get it right first time. Imagine finding yourself in front of an extremely valuable and prestigious skin that you have waited long time for and which has cost a large amount of money: what a weight of responsibility rests on the scissors that are going to cut into it! Another factor must also be kept in mind: the leather must be cut so that it corresponds perfectly to the Designer's original concept, to make the most of the skin's natural patterns and designs, and to enhance the shape and originality of the finished article, and the stitching must also be carried out in a certain way.  Once the skin has been skilfully cut, the next stage is the stitching of the handbag. The artisan who takes care of this part of the production is called the BANCONISTA, which can be translated as the ASSEMBLER. He must be an experienced Master Leather Craftsman, having to put together the bag, recreating the paper model from actual leather. The leather is either hand-stitched or stitched with the simplest of sewing machines, which allow finer, straighter and tougher sewing of the more difficult parts. It is very intricate work and must be carried out with meticulous care and attention. The Banconista needs a huge wealth of experience to be able to stitch fine, straight and symmetrical seams on leather, especially on rigid leathers such as crocodile or Ligator croc, where every detail must line up perfectly against the next. Unlike sewing common fabrics, on leather one false stitch leaves a permanent mark, as the holes made by the needle don't close up again, leaving the bag irrevocably damaged, so the Banconista must be totally precise in his work. The more pockets and accessories on the bag, the longer and more complicated it is to make. The final quality and prestige of the finished product are completely dependant on this stage of preparation and stitching. If the bag is stitched carelessly or in a hurry, or if it is sewn by an inexperienced person, or someone who lacks passion and commitment to his work, the bag suffers noticeably: its appearence changes and is different from the original design, more anonymous: it certainly won't live up to our expectations and the quality product that we wish to create for you. We are totally convinced that our genuine Italian leather artisans, being very experienced in this sector, are perfectly able to create a wonderful luxury product, whose brand 'Made in Italy' is a real source of pride and prestige either for us or for our customers.  Another step of the production is the finishing of the handbag. Before this stage the bag has been stitched, but not completed and still looks quite different from the finished product. It lacks all the important details, such as buckles and zips, and the leather itself is still unfinished. The bag's appearence is still impersonal and anonymous. During the FINISHING process the handbag is carefully examined, perfected and all the final accessories and hardware are added. At last the bag is finished and ready to be purchased. It has been transformed from a two dimensional drawing on paper to a tangible reality. The finished handbag is carefully wrapped in the softest tissue paper and put into a special red fabric pouch to be shipped to the customer who has ordered it.

From this brief overview of the production of our handbags, it is easy to see that a few important components are essential to the creation of a luxury and prestifious handbag:

A genuine luxury article can only be produced when the following conditions come together:

Nevertheless the elusive quality that makes each of our handbags so special is the fact that our leather craftsmen put their whole heart and soul into every stage of their work, imbuing each of our bags with that magic ingredient that only comes from being personally hand-made with love and care, and transforms it into a wonder of refinement and beauty. Their most important job is to give a little piece of themselves to every bag they make and guarantee a truly prestigious product. Perhaps it is this one component that is most important of all to make a successful luxury bag, and we promise you our craftsmen have more than enough of it to spare!

|